Le morsettiere per guida DIN consentono il collegamento affidabile di due o più conduttori mantenendo il massimo ordine nella cassetta di distribuzione. Sono disponibili morsetti per conduttori di diametri diversi e sono consentiti diversi carichi di corrente.

A seconda della funzione dei conduttori collegati (di fase, neutro o di protezione), i colori diversi sono una caratteristica ovvia. I morsetti sono fissati alla guida DIN TS35 o TS15 con un semplice scatto. Anche lo smontaggio è molto veloce.

Il conduttore è collegato al terminale con il sistema Cage Clamp o il più recente Push-in Cage Clamp senza utilizzare una vite. Entrambi i metodi garantiscono un contatto molto affidabile, risparmiando tempo durante l’installazione. Lo smontaggio del giunto è altrettanto veloce.

La differenza tra le due tecnologie consiste nel fatto che per inserire il conduttore nel terminale CageClamp è necessario "aprire" il terminale con un cacciavite o un attrezzo simile, mentre quando si parla di Push-in CageClamp basta spingere il cavo rigido o a trefoli con un manicotto nel terminale. L’attrezzo è necessario solo per un cavo a trefoli senza manicotto.

E perché dovresti scegliere queste morsettiere senza viti di WAGO? Perché sono veloci, resistenti agli urti e, soprattutto non richiedono manutenzione. Nessun controllo regolare: non è più necessario serrare le viti.

Oltre alle morsettiere per guida DIN, offriamo anche una vasta gamma di accessori: piastre terminali e intermedie, barre a ponticello, cassette ed etichette di marcatura.

Le piastre terminali e intermedie vengono utilizzate per terminare in modo sicuro una serie di morsetti su una guida DIN. La barra a ponticello di collegamento collega in modo conduttivo due morsetti adiacenti. Nella scelta, prestare attenzione alla dimensione corretta in base alla dimensione della morsettiera.

Le cassette vuote ti consentono di montare i tuoi componenti elettronici su una guida DIN. Grazie alle etichette di marcatura, avremo ordine e una buona panoramica nella cassetta di distribuzione.

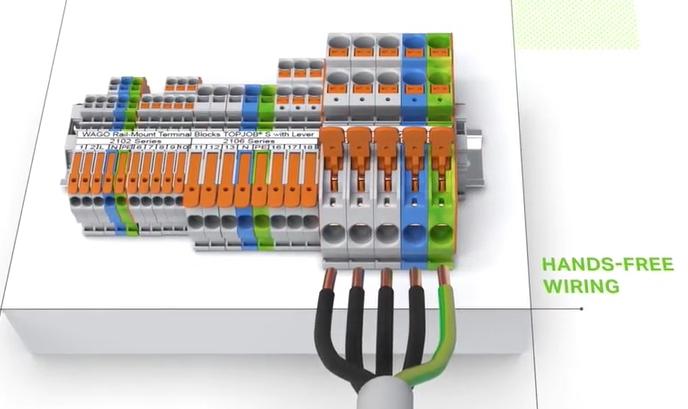

Serie TOP JOB S

I morsetti Wago più popolari provengono dalla serie TOP JOB S con il sistema Push-in CageClamp, che sono circa il 30% più piccoli di quelli della generazione precedente di TOP JOB con il sistema CageClamp. Ma entrambe le serie hanno i loro fan.

Le ultime novità sono le morsettiere della serie TOP JOB S con leva (serie 2102, 2106 e 2116) o con pulsante dalle serie 2200 a 2216. La leva elimina la necessità dell’attrezzo durante l’inserimento e lo smontaggio (può essere maneggiato anche con una sola mano) e il pulsante aumenta il comfort e il controllo visivo durante l’utilizzo dell’attrezzo.

Si consiglia di scegliere le serie di morsetti 260, 261 e 264 quando non si dispone di spazio maggiore. Hanno una vasta gamma di opzioni di montaggio, anche su piccole guide DIN TS15, sul pannello con viti o piedini a scatto. E la cassetta di distribuzione sembra di nuovo a posto se si utilizzano morsetti della serie Wago con conduttori laterali delle serie 279, 280, 281 e 282.

L’elenco seguente mostra le tipologie base di morsettiere Wago per guida DIN della nostra offerta, immediatamente disponibili direttamente dal nostro magazzino. Troverai un elenco completo dei morsetti per guida DIN nel nostro negozio online.

Se hai bisogno di maggiori informazioni sui prodotti WAGO o desideri un consiglio, non esitare a contattarci scrivendo a sales@soselectronic.com

The TOPJOB®S family, with push-in CAGE CLAMP®, introduced push-in wiring for rail mount terminal blocks. The family now offers levers and push-buttons for convenient and intuitive wire termination while maintaining the vibration-proof, gas-tight, corrosion and thermal-cycling resistant connection.

Ti piacciono i nostri articoli? Non perderne nemmeno uno! Non devi preoccuparti di nulla, organizzeremo la consegna per te.