As we all know, it´s more than advisable to think of an enclosure already at the very beginning of the device design and to partially adjust a PCB design to a given enclosure. Otherwise, it can easily happen that despite a huge offer of enclosures on the market, we cannot find a suitable size for a given PCB, mainly in respect to a position of connectors and mounting openings.

1. Material choice alias Plastic or Metal?

Plastics

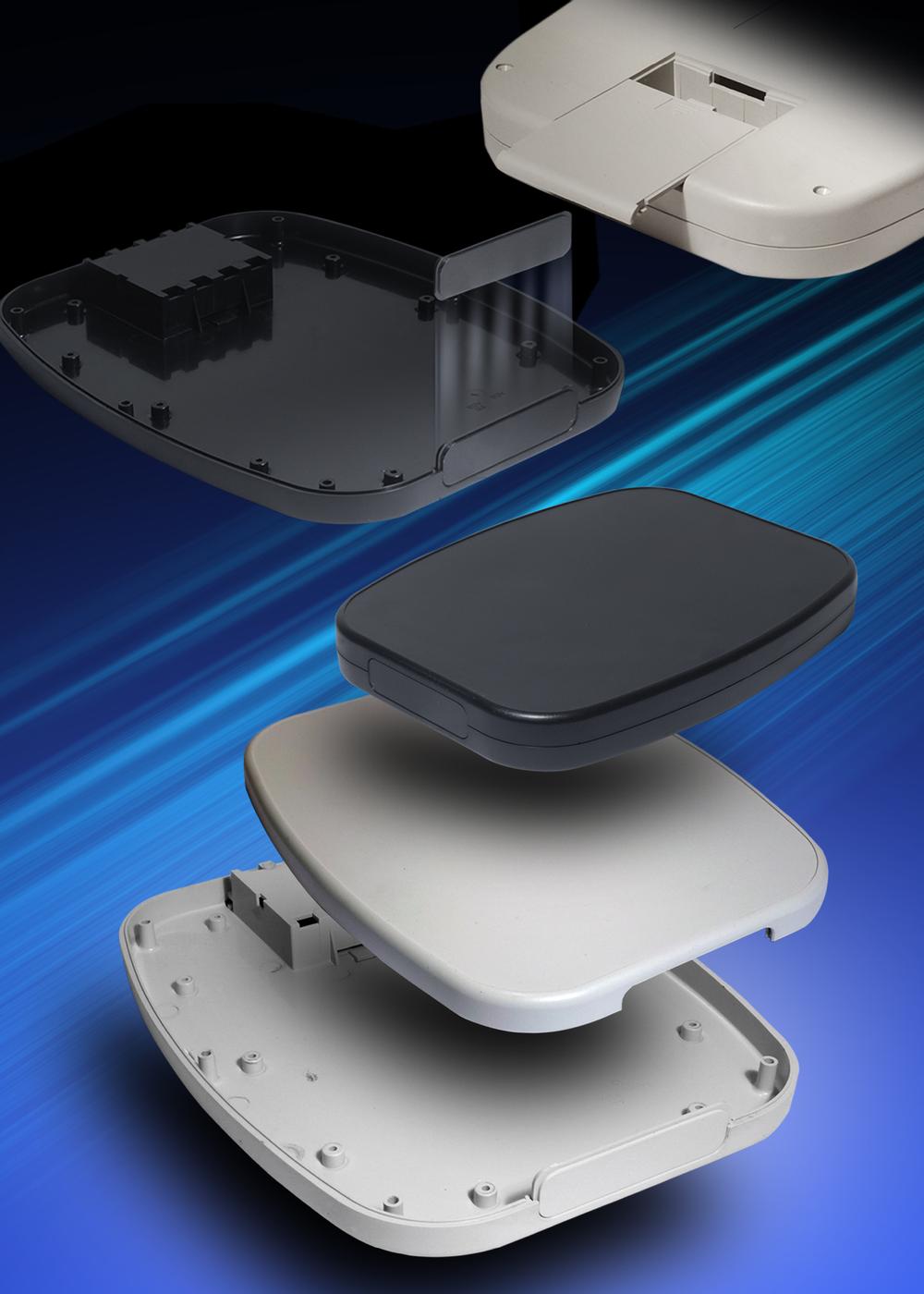

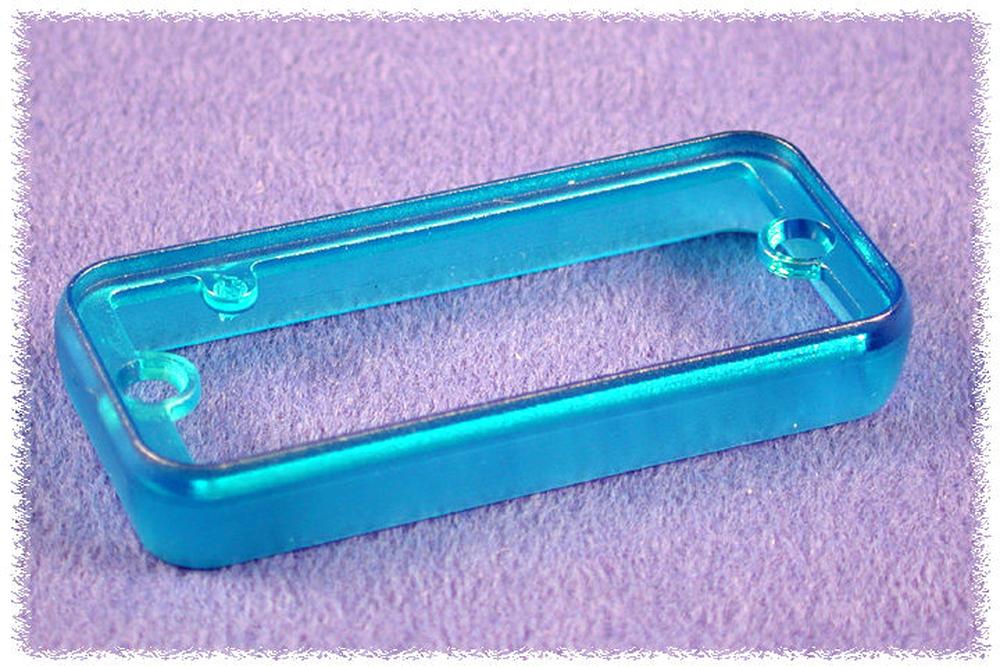

The most widely used plastics for production of small electronic enclosures are ABS, PC (polycarbonate) and polyester (glass reinforced).

Advantages of plastic enclosures are mainly insulating features, considerable shock resistance (however, from a certain level of deformation, cracking may occur), easy machining (milling, drilling, ...), resistance to many aggressive agents, mainly acids and alkali.

As for drawbacks, plastic enclosures are usually fragile at very low temperatures, they have weak heat conductivity resulting in a lower cooling of components (unless the enclosure has ventilation openings). Resistance to organic solvents and UV radiation is usually relatively lower, even though it depends on a given material.

If you go for plastic ones, then in the wide portfolio of Hammond brand you´ll probably find the right solution for you. Hammond enclosures are very precisely moulded, without faults, sharp edges etc. Colour shade is the same from batch to batch and a wide range of sizes and accessories further simplifies the choice of the right type for your PCB.

Metal

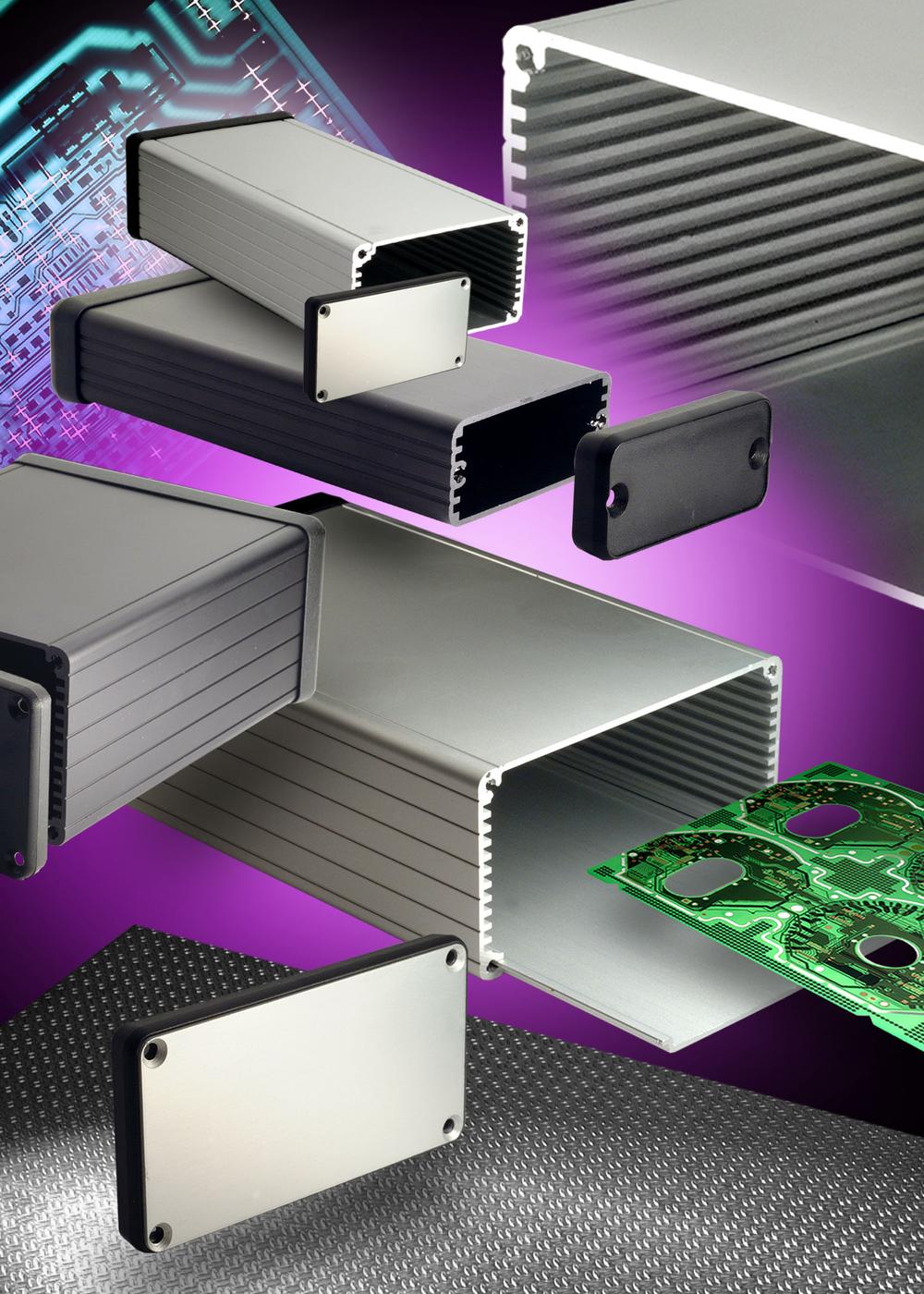

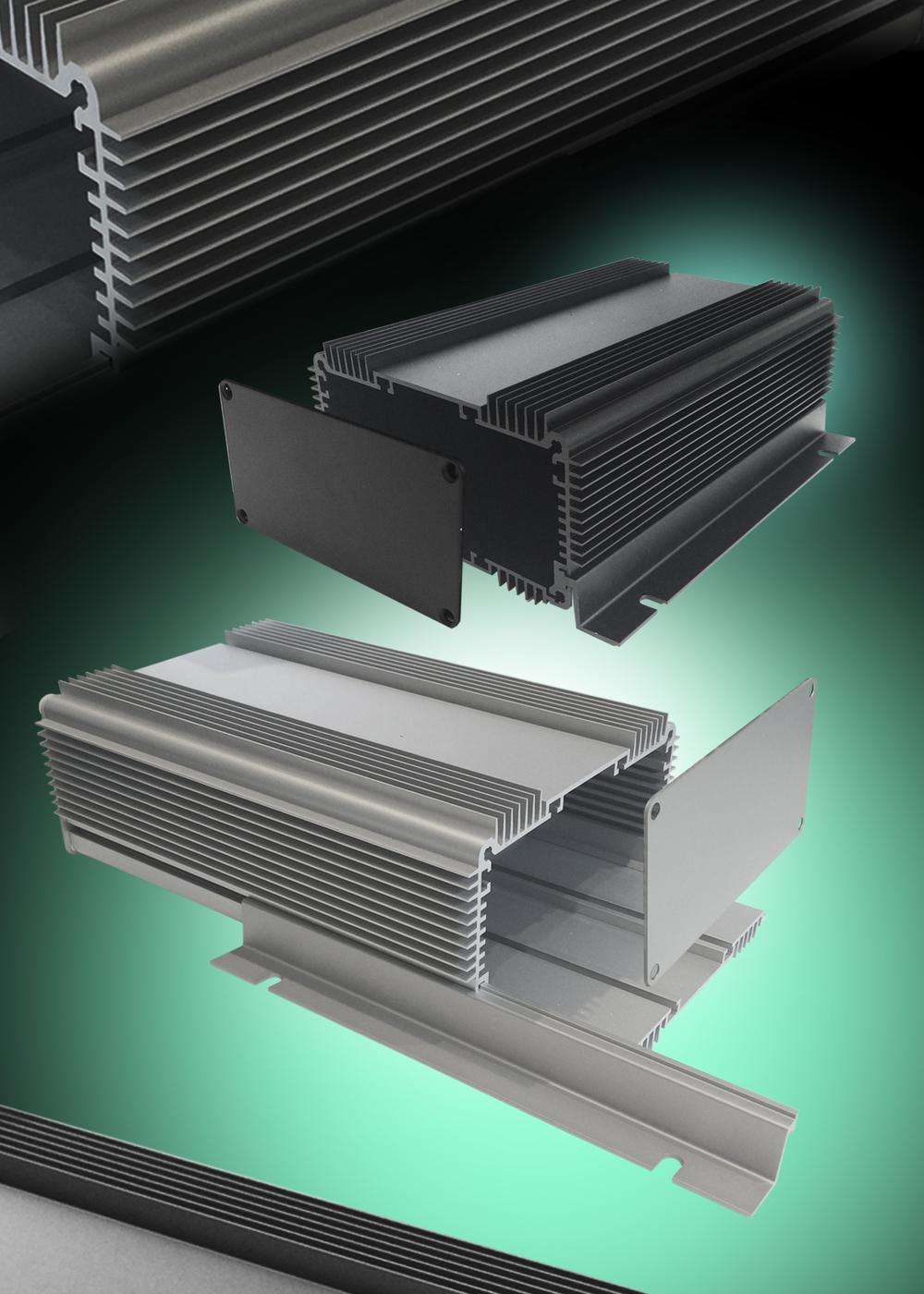

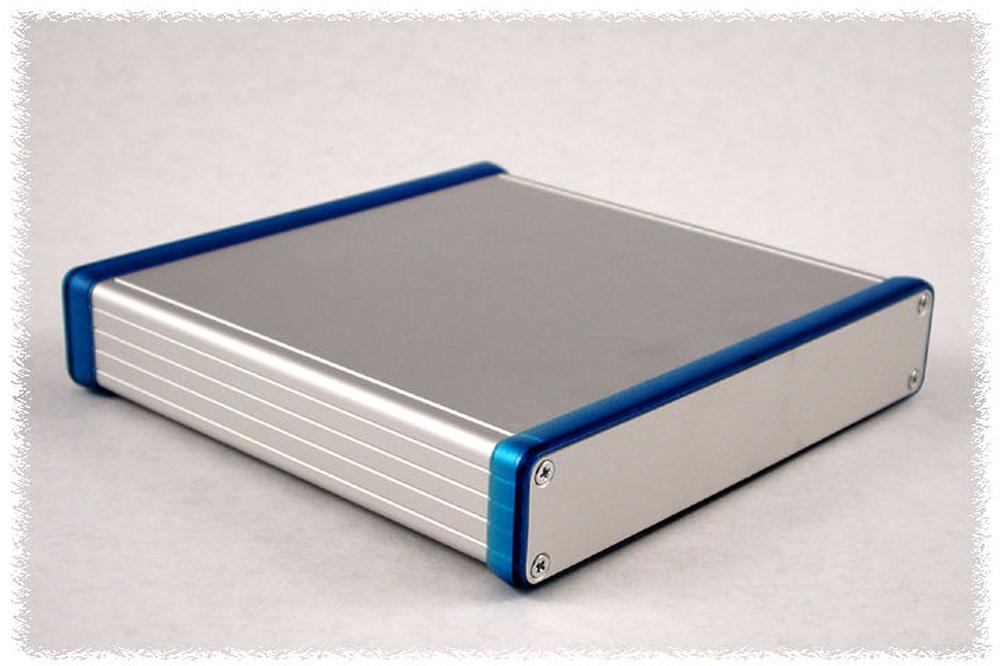

Small metal enclosures are in majority of cases made of aluminum or aluminum alloy (AlMgSi). Some of the advantages of aluminum are rigidity, shock resistance (from a certain level of shock, a permanent deformation occurs, however, it cracks only rarely), resistance to a wide temperature range, good thermal conductivity, resistance to organic solvents and to UV radiation. Electric conductivity is a base of great shielding properties (EMC), even though for a really good shielding, it´s necessary to use a conductive sealing or a design of an enclosure that ensures a continuous conductive joint of enclosure parts.

There are only a few disadvantages of aluminum enclosures, probably the only main one is a weak resistance to acids and strong alkali.

For a harsh environment, a stainless steel (inox) enclosure is usually an ideal choice. Inox can be labeled as almost ideal material in terms of resistance to all adverse effects.

However, as for production and consequent machining (drilling, milling), the inox is a very demanding material, and moreover relatively quite expensive.

If you decide for aluminum, then you´re at the right address. Hammond has a wide range of types in a huge amount of sizes, with a rich offer of accessories, moreover with various surfaces and in various colors of bezels.

2. Enclosure shape

This is really individual and mainly given by aesthetic feeling of a designer, as well as by requirements of a PCB design. For example, an elongated shape of a PCB (and an enclosure) makes it easier to separate the power (noisy) part from the sensitive low noise part. On the other hand, a squared shape usually enables an easier PCB design and shorter tracks.

With or without a flange?

Almost every enclosure can be mounted to a panel or a wall even if it doesn´t have a flange. A similar service is provided by additional mounting holders that are available to many enclosure types. Several industrial enclosures, like for example Hammond 1457, have inner mounting openings outside the sealing, thus they are enabling to fix the enclosure without decreasing the IP rating and also to hide mounting screws below the top cover.

Flange has a big advantage in a totally trouble-free mounting of enclosure. There´s no need to pen the lid or even to mount screws near sensitive electronics.

PCB mounting in an enclosure

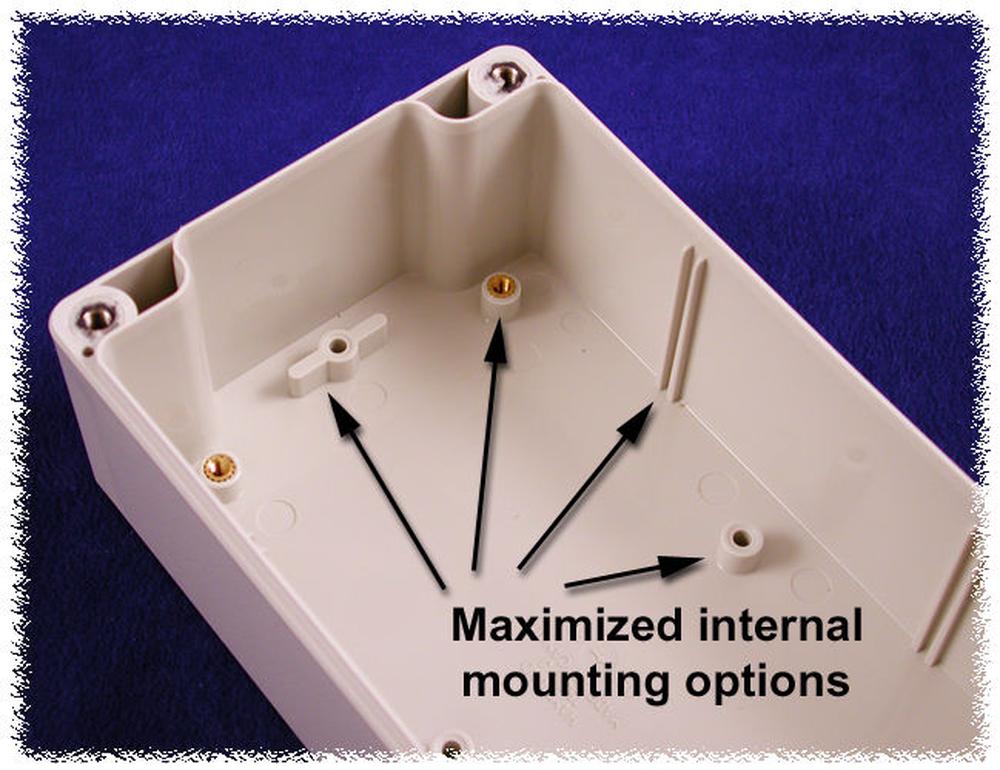

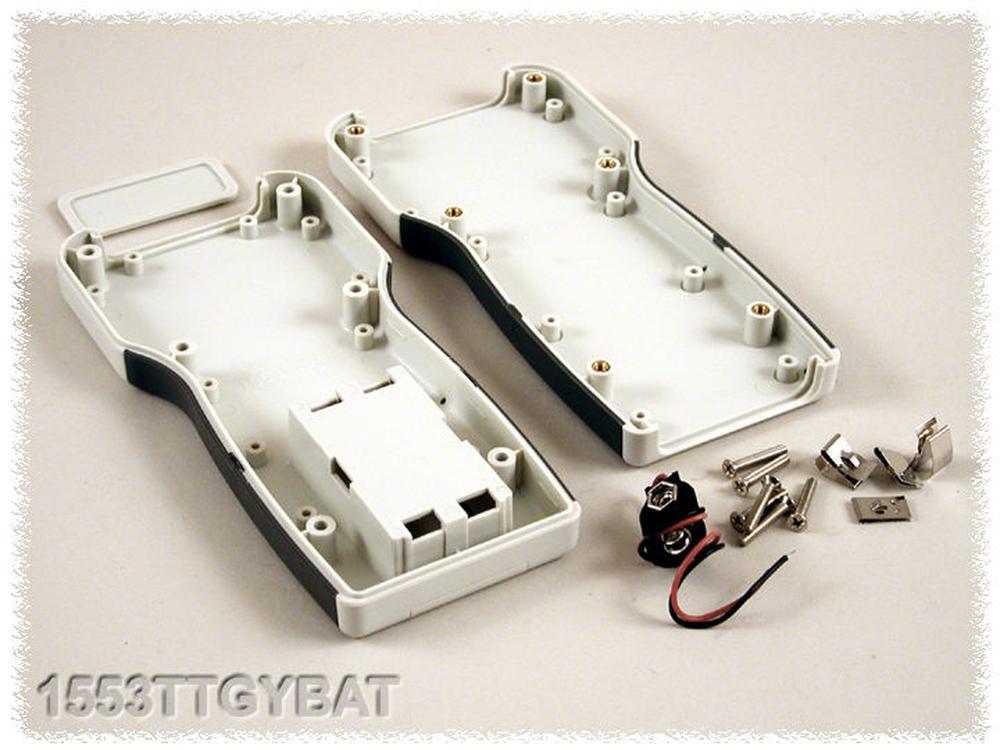

Perhaps the most widely used method is to mount PCB on various standoffs, which are very common at plastic- as well as diecast aluminium enclosures. Another widely used possibility is to insert PCBs into various slots that are typical for some series of enclosures and mainly for extruded aluminium enclosures. Some plastic enclosures combine all of these PCB mounting methods - like for example Hammond 1554 series, even with two types of spacers - with and without brass thread bushings.

3. Further aspects

A possibility to be different...Yes, even in electronics, the look has a big influence on the sales ability of the product. From this point of view, it´s certainly beneficial if some series are available in a wide range of color versions (for example Hammond 1455, 1590 and other).

Accessories

Spare screws, screws for inner standoffs, separately available panels and bezels, battery clips, DIN rail holders and others are also welcome. A possibility to buy only a cover or a panel without the necessity to buy the whole enclosure (for example to tune the milling process) is a common thing for serious producers like Hammond.

Documentation

Detailed documentation has two aspects. Naturally, it´s very helpful at the device design and it also binds a producer to really maintain all detailed dimensions, radiuses in corners and similar. Every producer will give you a basic datasheet. A bonus is if a common datasheet also contains an active 3D model (usually a part of the pdf format), which helps you get the idea about the enclosure when you´re only choosing and you don´t have it in your hands.

Higher levels are CAD 2D and 3D models in common formats (stp, ....). Some producers provide this documentation only upon request or after logging in and for example, Hammond has it freely available (without any requests for logging, e-mail or so).

Technical support

Whether it´s only a requirement for non-standard size, or even some problem occurs, a serious producer will make everything possible to solve it to satisfaction of a customer.

From long-term cooperation with company Hammond, we can say that we already successfully solved many special requirements of our customers.

The possibility of custom modifications directly at producer

Nowadays it´s usually time and cost saving to modify an enclosure according to your demands directly at the producer. This way we´ll save another step at sub-contractor and we´ll gain prompt deliveries in a 100% quality.

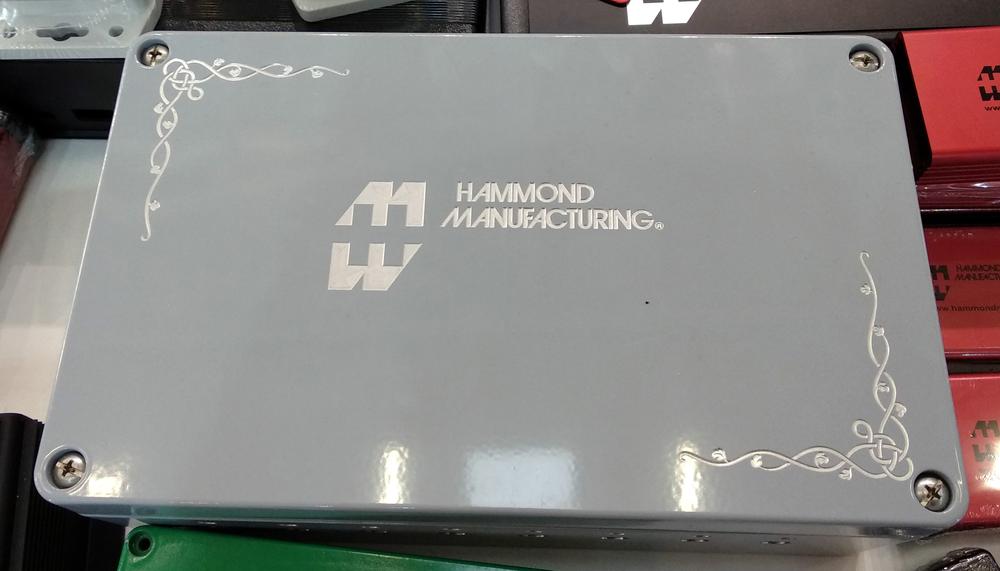

Hammond newly offers, besides drilling and milling of openings for connectors and similar, also modifications related to aesthetic aspect, for example, milling of your logo, which looks truly impressively on aluminum enclosures.

A nice and comprehensive overview of various shapes and sizes of plastic and metal enclosures is described in the Hammond leaflet.

COMPETITION:

The competition has been published here, in which you sent us your applications in Hammond enclosures. Thank you for your participation and congratulations to the winners. We will contact them by email.

In case of interest in any enclosure, please contact us at sales@soselectronic.com

- high-quality enclosures from the producer with over 100 years of experience

- wide range, a lot of shapes and sizes

- wide range of accessories

- possibility of custom modifications directly at producer

- stable quality (color shade, dimensions,...)

- reliable deliveries on time

Hammond Manufacturing provides wide possibilities of modifications to get ready-to-use enclosure for your product.

Do you like our articles? Do not miss any of them! You do not have to worry about anything, we will arrange delivery to you.