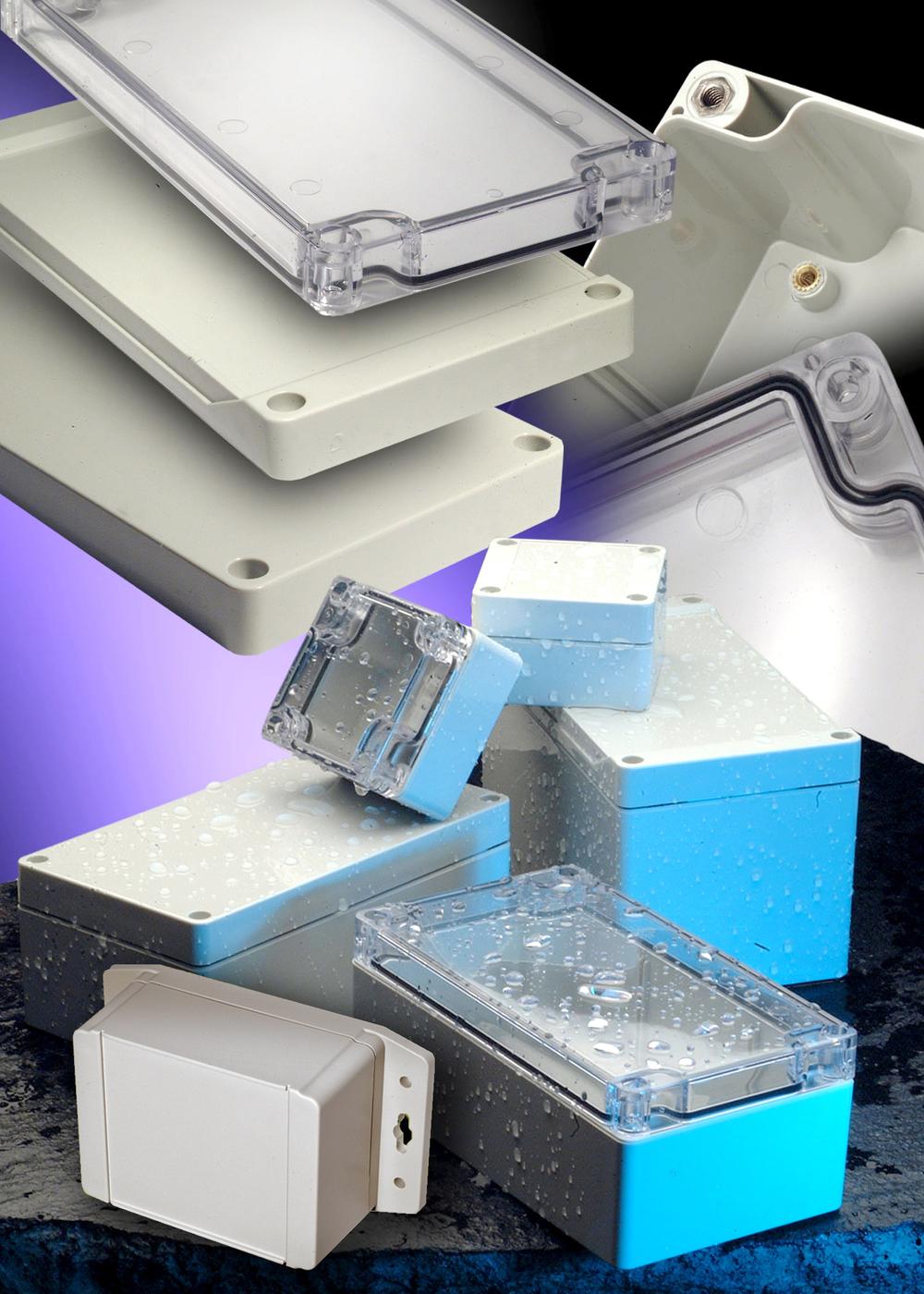

Le note custodie industriali Hammond delle serie 1554 e 1555 sono da tempo tra le migliori nel settore delle scatole di plastica robuste. Se stiamo cercando una buona via di mezzo tra resistenza meccanica, elevata resistenza a vari impatti negativi e costo, le serie 1554 e 1555 sono sicuramente una scelta affidabile.

Le tipologie di custodie "standardizzate", offerte da vari produttori, spiccano sul mercato da decenni. Tuttavia, se esaminiamo nel dettaglio l’offerta di vari produttori, troviamo piccole differenze che in definitiva hanno un impatto sostanziale sul fatto che la scatola soddisfi o meno le nostre esigenze e aspettative. Spessore della parete, qualità della plastica, opzioni di montaggio del PCB interno, accessori... questi sono solo alcuni aspetti chiave.

Hammond ha dato alle serie 1554 e 1555 tutto ciò di cui avevano bisogno e recentemente ha aggiunto 6 nuove dimensioni, che insieme formano 36 nuove configurazioni.

Qual è la differenza principale tra le serie 1554 e 1555?

La 1554 è una serie classica consolidata disponibile sia in ABS che in PC (policarbonato). Le viti in acciaio inossidabile e le boccole filettate in acciaio inossidabile eliminano praticamente la corrosione e la guarnizione in silicone di alta qualità unita a un design di precisione consentono un livello di protezione IP68 per le versioni in policarbonato (PC). Il fondo della scatola è sempre grigio chiaro (RAL 7035) e il coperchio può essere grigio, trasparente o fumé.

La serie 1555 si basa sulla serie 1554 ma rappresenta un’alternativa più moderna. Presenta una superficie elegantemente incassata sul coperchio per una facile installazione di, ad esempio, una tastiera a membrana, varie etichette ecc. Allo stesso tempo, ha anche distanziatori per PCB sul lato interno del coperchio (non solo nella parte inferiore).

Le versioni in policarbonato hanno un’elevata resistenza ai raggi UV e sono quindi adatte anche per l’uso esterno.

Le nuove dimensioni disponibili per le serie 1554 e 1555 sono:

● L: 105 x 105 x 60 mm ● LA: 105 x 105 x 90 mm

● Q: 140 x 140 x 60 mm

● QA: 140 x 140 x 90 mm

● W: 180 x 180 x 60 mm

● WA: 180 x 180 x 90 mm

Le tipologie selezionate sono reperibili direttamente nel nostro magazzino. Tutte le altre tipologie possono essere consegnate su richiesta in tempi brevi e a prezzi competitivi.

Se stai cercando uno qualsiasi dei prodotti HAMMOND, o hai bisogno di maggiori informazioni, siamo lieti di aiutarti. Scrivici all’indirizzo sales@soselectronic.com

- Le versioni in ABS sono stampate in materiale per uso generico, con una classe di infiammabilità pari a UL94-HB. Per uso interno.

- Le versioni in policarbonato sono resistenti ai raggi UV per uso esterno. Il policarbonato grigio ha una classe UL94-5VA, mentre i coperchi chiari e fumé hanno una classe UL94V-0.

- Il coperchio con guarnizione con costruzione a “maschio e femmina” in due pezzi fornisce protezione contro l’ingresso di olio, polvere e acqua.

- La guarnizione sostituibile è un pezzo unico realizzato con silicone ad alta temperatura e viene fornita separatamente all’interno della custodia (non preinstallata).

- Le versioni in plastica ABS sono progettate per soddisfare l’IP66.

- Il coperchio è fissato con viti senza dado in acciaio inossidabile M4 incluse che sono filettate in boccole in acciaio inossidabile integrate per il montaggio e lo smontaggio ripetitivi. Tutto l’hardware è in acciaio inossidabile per evitare la corrosione causata da metalli diversi.

- Le viti del coperchio sono autobloccanti (i fori del coperchio sono filettati con la prima installazione delle viti del coperchio).

- Le caratteristiche interne sono ottimizzate per le opzioni di montaggio e variano in base alle dimensioni:

- Schede di montaggio su guida DIN interne stampate nella maggior parte dei modelli, ad eccezione delle dimensioni “C” e “D”;

- Inserti e/o distanziatori in ottone (viti autofilettanti n. 6) integrati filettati (M3) per montaggio su circuito stampato o pannello interno in tutte le dimensioni tranne quelle più piccole (“B”);

- Le guide verticali della scheda PC (per circuiti stampati di spessore pari a 1,5 mm) sono modellate in tutte le dimensioni tranne la più piccola ("B").

Ti piacciono i nostri articoli? Non perderne nemmeno uno! Non devi preoccuparti di nulla, organizzeremo la consegna per te.