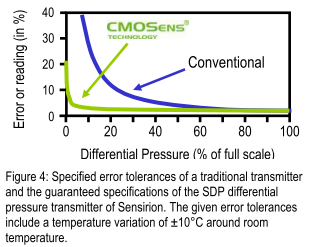

Ventilation, air conditioning (HVAC), or any other applications, where a pressure or a flow of air (gas) is essential, can be precisely regulated only if we know a real pressure/ flow conditions. Monitoring of fans functionality, status of filters, …, even for this purpose are very suitable differential pressure sensors from Swiss company Sensirion with an excellent accuracy and long-term stability.

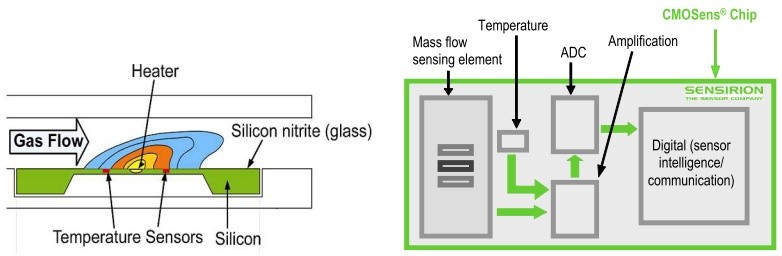

As SDP sensors are differential, they have 2 nozzles. The base of these sensors is a miniature heating element and two temperature sensors. Difference of pressures will cause a small air flow through a component and it will cause a temperature difference in these built-in sensors. Temperature difference is directly depending on the amount (weight) of air flowing through a sensor and it naturally depends just on a pressure difference. A great advantage against membrane pressure sensors is a long-term high accuracy even at measuring of small pressure and maintaining of accuracy of a “zero point”.

As an air specific weight depends on temperature, measurement based only on a temperature difference of two internal sensors wouldn´t be accurate. That´s why SDP sensors have a built-in temperature compensation and linearization, thus an output of a sensor is directly a value usable for further processing. Resolution of sensors is very high and is user selectable in a range of 9-16 bits. Resulting binary value read-out through I2C interface can be divided by a constant shown in a tab. 2.1 on page 3 of the SDP6xxv1.7 datasheet and we´ll get a resulting value in desired units (Pa, bar, inch).

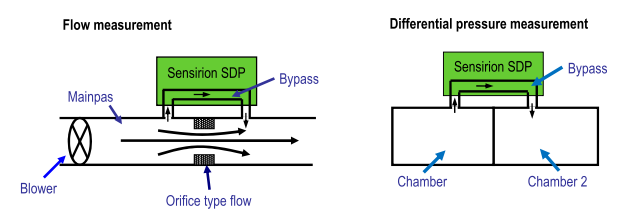

Relatively simply. All that is necessary is to make a small orifice in a pipe and this way to create a “resistance” as described in the SDPxxx_Bypass_Configuration application note. In an electronics analogy the differential pressure measurement is similar to measurement of voltage on a resistor, which depends on a current flowing through a resistor. SDP sensors can be used even for measurement of a pressure difference in a given pipe against a surrounding environment, in such a way, that one nozzle of sensor will be left “unconnected”. Naturally, such a configuration can only be used if a small leakage of a measured “gas” (air) is acceptable.

Detailed information will provide you the SDP600 datasheet as well as documents SDP600_Sensor_Selection_Guide_V2, CMOSens_for_HVAC, SDP6x0_Changing_Measurement_Resolution and SDP6x0_Pressure_Drop_In_Hose.

- measuring of a differential pressure

- flow measurement at a „bypass“ configuration

- calibrated and temperature-compensated

- outstanding repeatability, even under 10 Pa

- accuracy better than 0.2% even near zero

- digital output with I2C interface

- outstanding reliability and a long-term stability

- 9-16 bit resolution (12 bit default)

- available in several versions

- bidirectional measurement

- can be mounted in any position

Do you like our articles? Do not miss any of them! You do not have to worry about anything, we will arrange delivery to you.

Competition with the following question has been published here:

What´s the difference of SDP606/616 sensors from other members of the SDP6xx series?