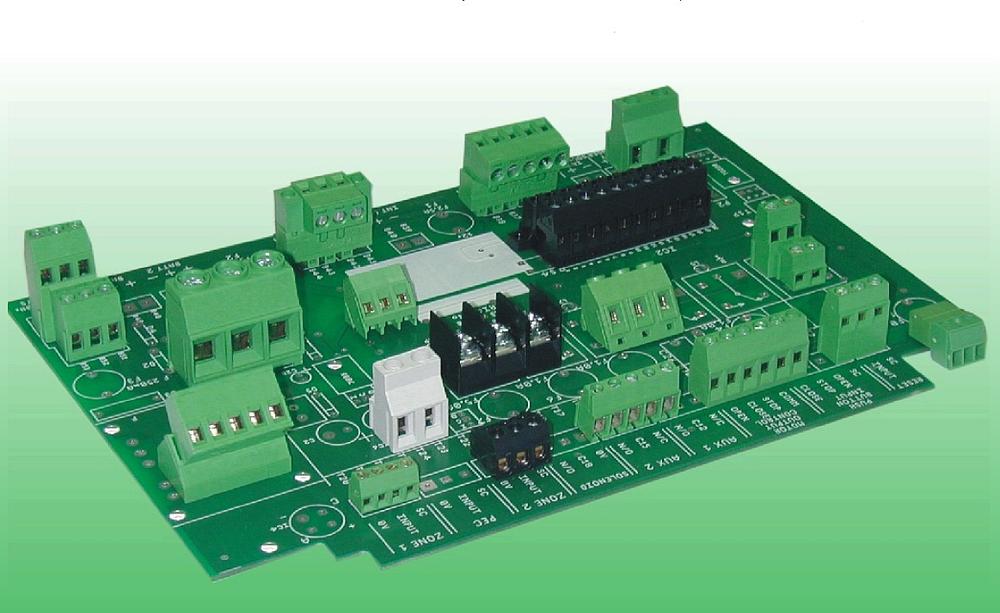

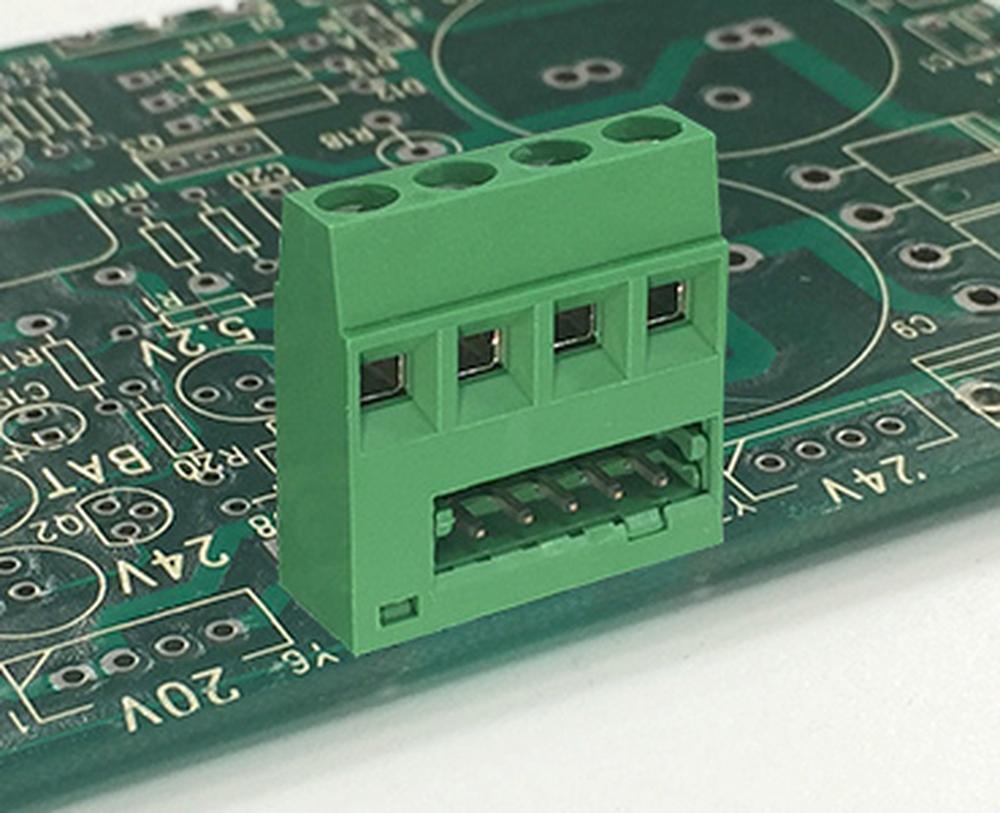

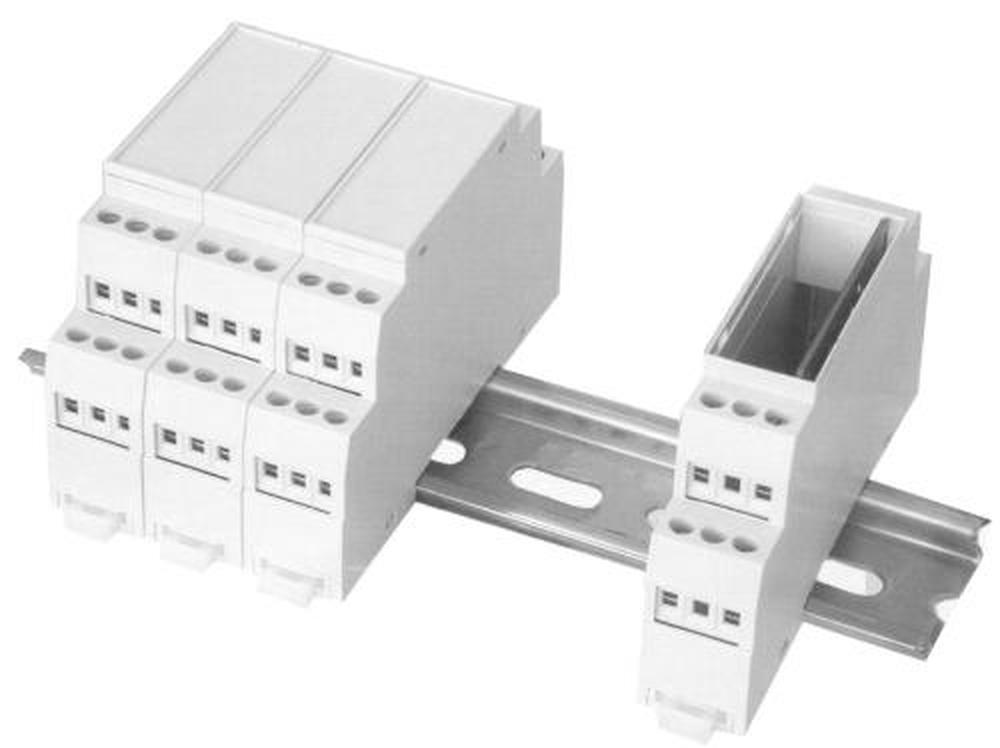

Euroclamp began the production of printed circuit terminal blocks in 1991. Thanks to their experience of about 30 years within the electronic field, we recognize them as a flexible, reliable and highly innovative company.

Why do we like Euroclamp?

Because the basic range of terminal blocks has never dramatically changed throughout all those years but has “only” been continuously improving - thus we’re having a certain guarantee of quality, supported by Integrated Company system (Quality, Environment, Safety) according to ISO standards

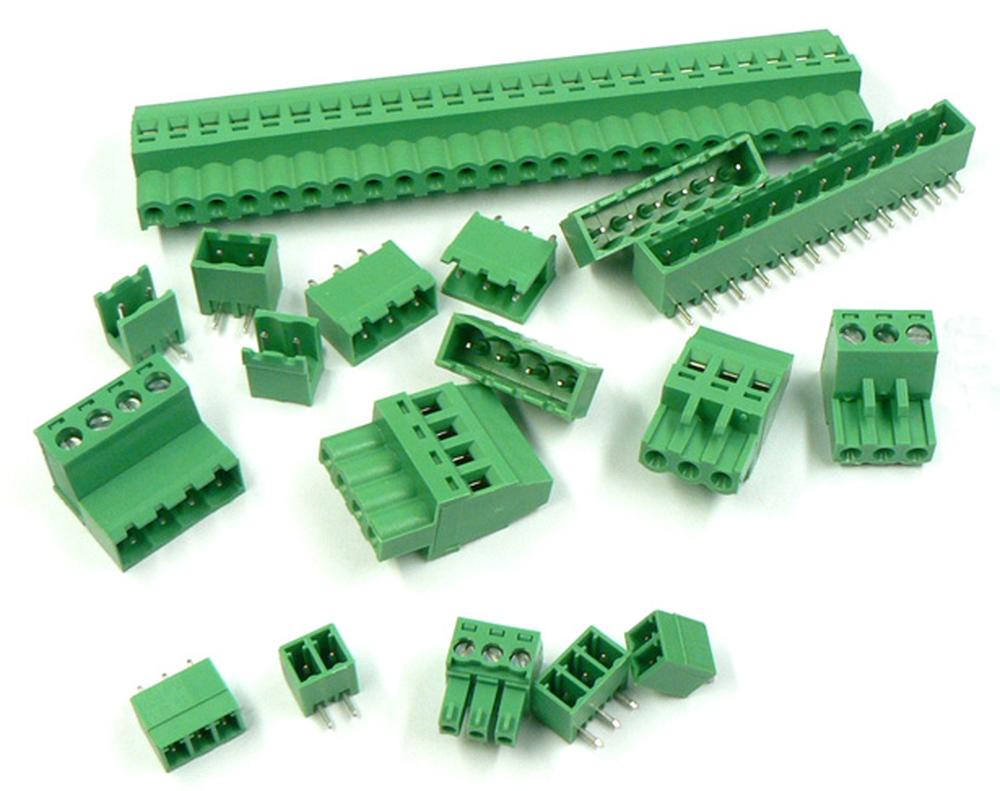

Extra features you should consider:

Specifically prepared surface treating (Sn 100%) in order to grant excellent soldering performances, even after a long stocking period.

Plating of contact in tin baths that ensures the “WHISKERS FREE” process.

Easy mounting peaky shaped pins.

Screws have a hardened surface that allows a high number of tightening and loosening cycles.

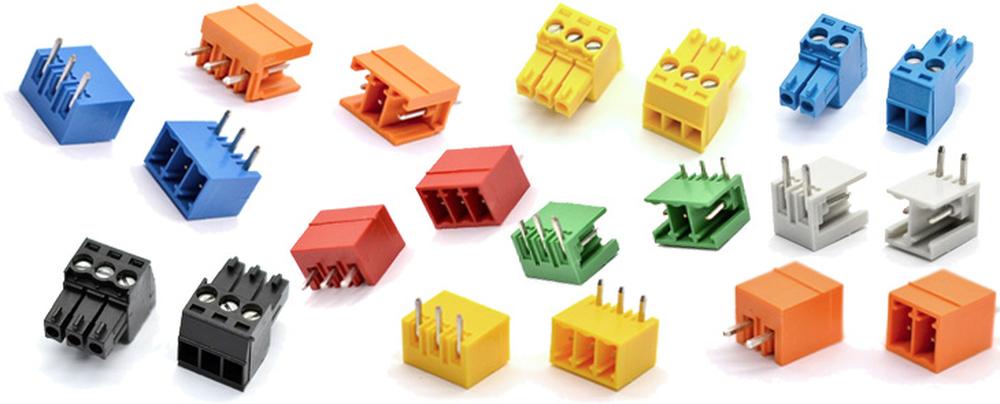

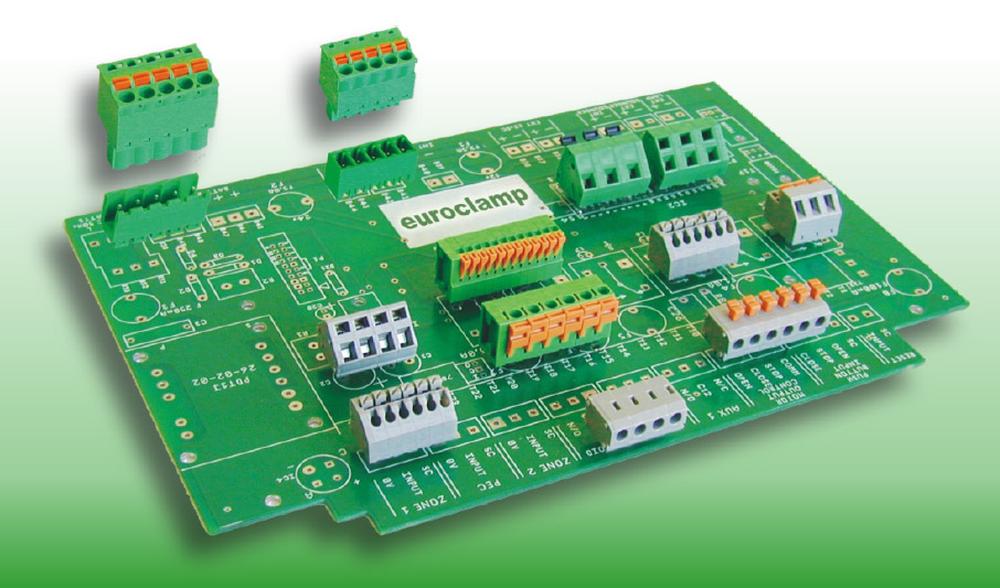

Euroclamp offers several connection systems for terminal blocks and plug-in connectors:

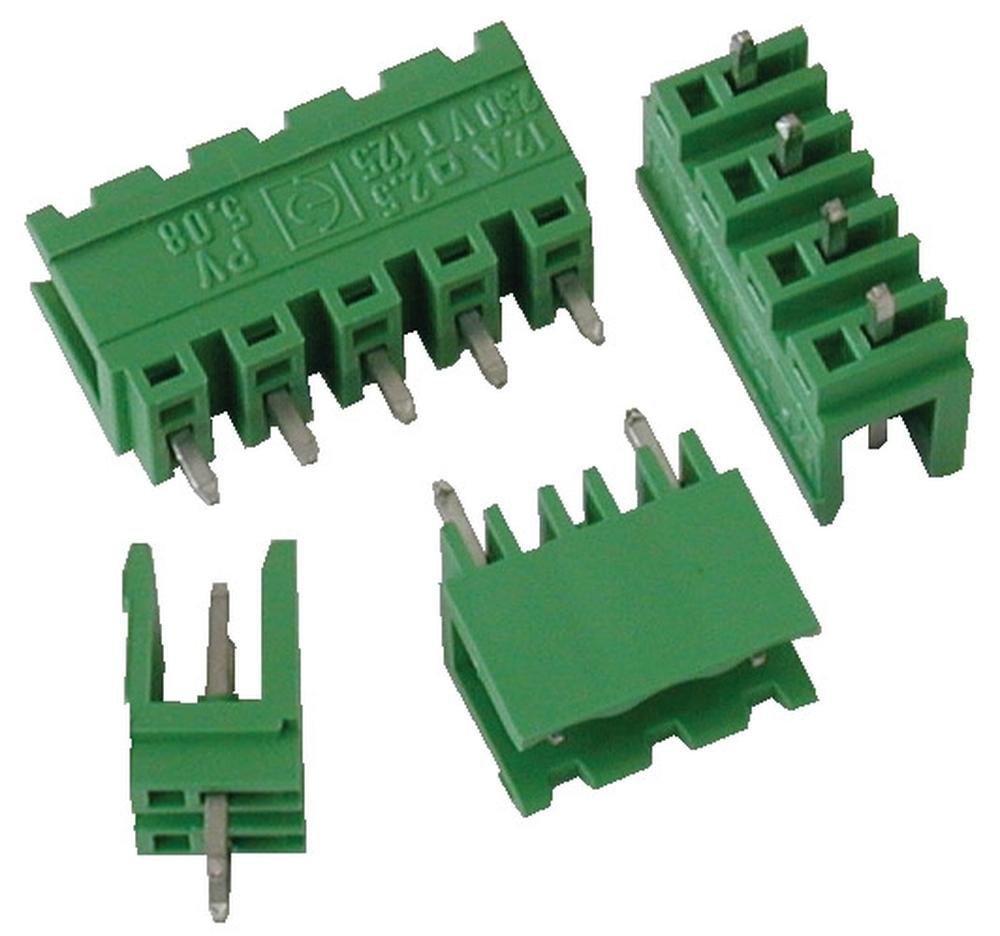

1. CAGE CLAMP - It is the easiest and cheapest system

2. RISING CLAMP - It’s the strongest screw type connection system. It allows a high number of actions (screwing down/up). Besides, it has a large contact surface and high clamping force

3. BARRIER - This system combines handiness and high clamping force

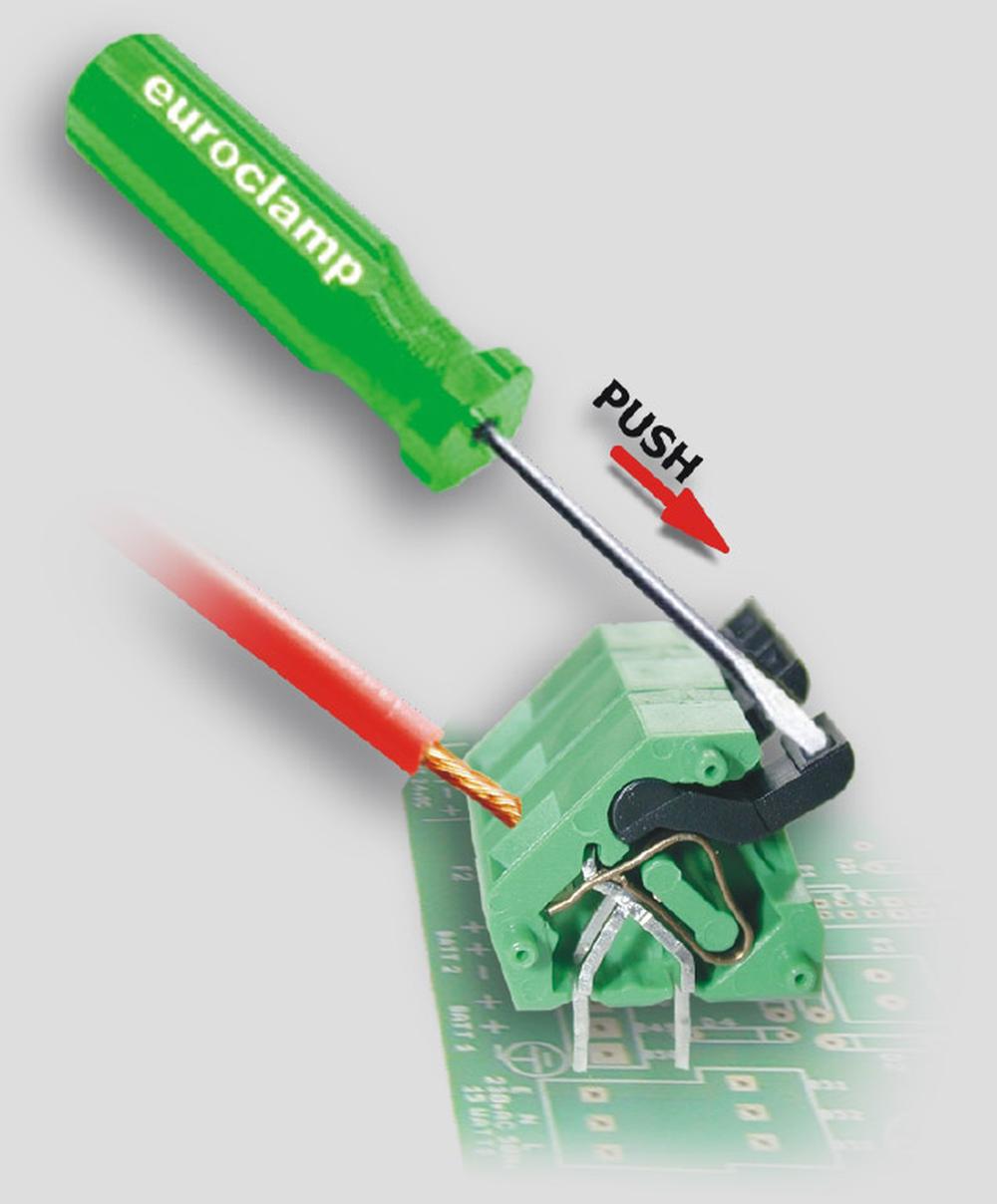

4. SPRING-CAGE - It is quick and easy to use. It involves the activating of the connection system (spring) by an appropriate tool or by a specific push-button that is fully integrated into the body of the terminal block

5. PUSH-WIRE - It allows the connection by pushing the wire (either solid or stranded with a push rod) into the terminal block. The connection and disconnection of the wire can be easily achieved with the aid of the special tool (screwdriver)

If you are a manufacturer of household appliances ask for “Glow Wire Test” compliant terminal blocks. Euroclamp can supply products in accordance with EN60335-1 that meet the requirements of IEC/EN60695-2-11.

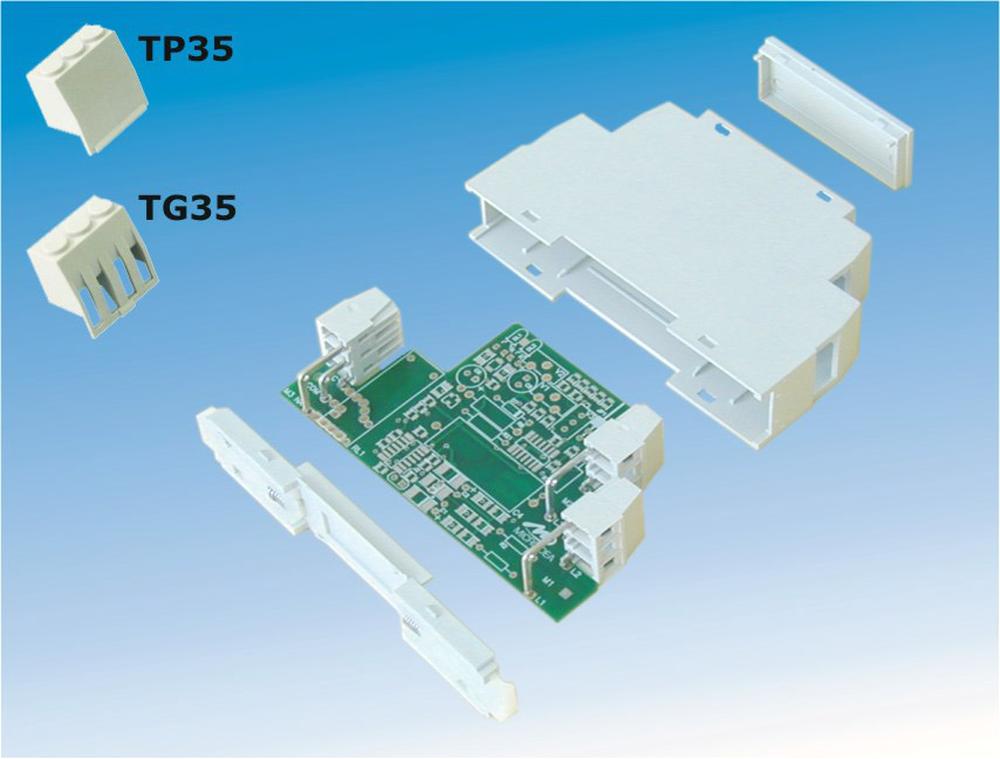

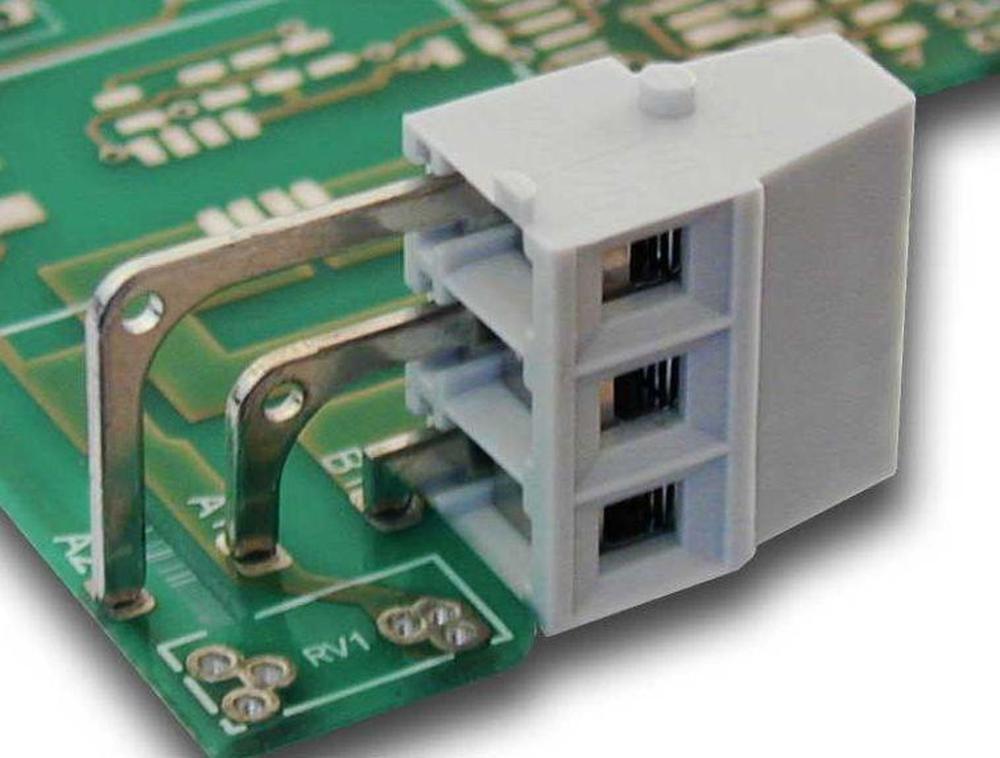

The electronics industry requires more and more soldering systems that are reliable, fast and easy. One of these is the soldering process called “through hole reflow” –THR- (or Pin-In-Paste). THR is processed using an oven at high-temperature levels (260°C). The plastic shells of THR products are made of high thermal performances UL94 V0 self-extinguishing, halogen, and red phosphor free material. Euroclamp can currently supply THR terminal blocks in black color.

THR connectors and terminal blocks can be packed in standard boxes or, if required, in Tape on Reel for the “PICK AND PLACE” automatic assembly of printed circuit boards. If you are ordering THR version of terminal blocks, please add “TH” to the part number. If you are requiring them in Tape-and-Reel packaging, please add “TAR” to the part number.

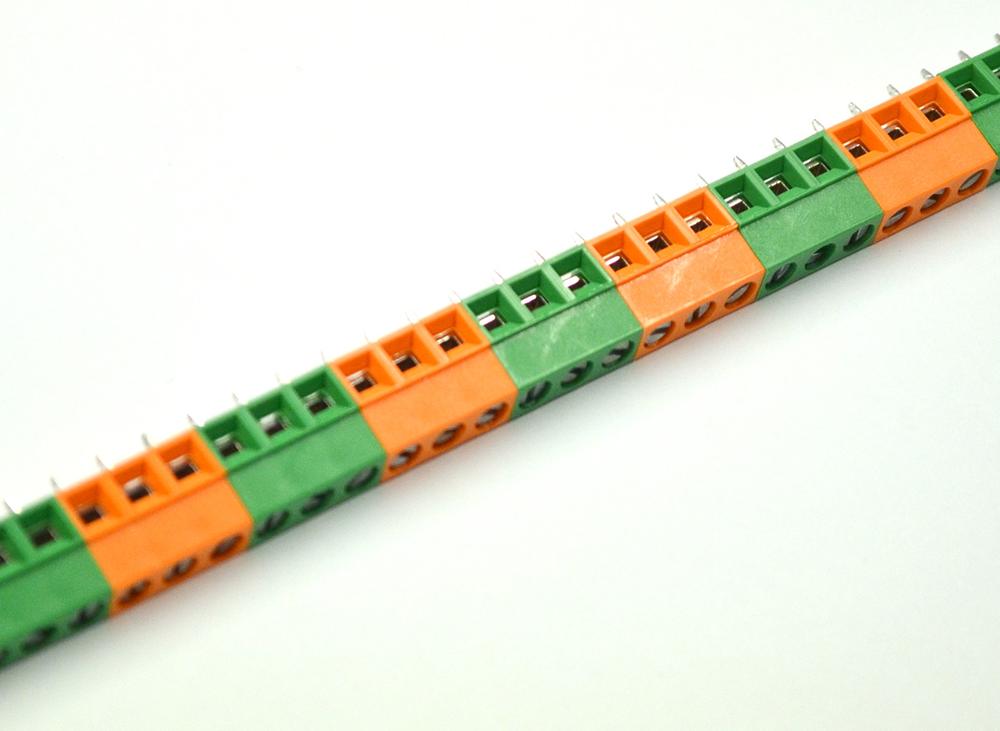

Another good service you can ask from Euroclamp is the marking. Terminal blocks and connectors can be marked either by pad-printing, or laser marking process or by means of self-adhesive labels. The pad-printing is made directly on the plastic housing with permanent ink in different colors. Euroclamp can laser mark parts too, upon request. However, it is necessary to use special plastic on the terminal block that is suitable for using a laser.

We keep almost 300 Euroclamp products in our stock. Hopefully, you find what you are looking for.

If not, do not hesitate and contact us at sales@soselectronic.com. Together with Euroclamp, we will certainly find the suitable solution.

Do you like our articles? Do not miss any of them! You do not have to worry about anything, we will arrange delivery to you.